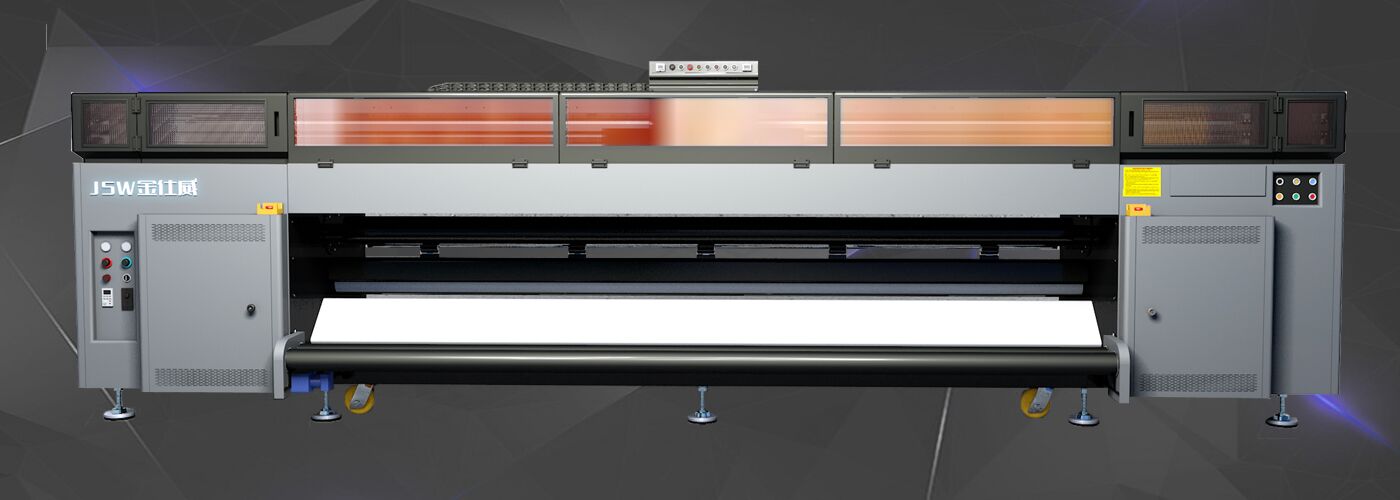

In the production of advertising spray painting, there are very strict requirements for the size accuracy of the image sprayed by the eco solvent printer. What about the lengthening or shortening of the print image of the eco solvent printer? Next, let’s explain it in detail.

The picture sprayed by the eco solvent printer will be shortened or elongated

First of all, with regard to the stepping accuracy of the eco solvent printer, if the equipment can adjust the “stepping”, it can be set or “compensation setting”. Moreover, as for the factors of the paper medium printed by the eco solvent printer, because of different materials, different thicknesses, different gram weights, different surface roughness and different friction coefficients, the resistance to the advance of the materials is different, fast and slow, but the running speed of the nozzle inkcart is the same; Therefore, during production, the compensation value needs to be corrected, that is, the stepping parameters of the machine need to be carefully adjusted according to different materials.

In the process of photo jet printing, the problem of retracting and releasing the printing paper medium is to relax the material in advance at the place of unwinding, so as to reduce the resistance of coil material. In the production process, there will be two phenomena: shortening and stretching, which is closely related to the tightness of materials. At the beginning, the material is relatively thick and the resistance is large. It is easy to shorten the picture, and the picture is easy to produce “horizontal lines”. The materials are getting thinner and thinner, which is easy to produce the phenomenon of picture stretching. The problem of lengthening or shortening has a great impact on the quality of inkjet image products, such as mismatched splicing, different lengths of mounted pictures, different lengths of pictures after mounting plates, etc.

Solution to the problem of shortening or lengthening the picture sprayed by the eco solvent printer:

1. Pay attention to the correctness of size in the design and output of photo sprayed images. When importing pictures with relevant RIP software, pay attention to keep the original size of the image unchanged, so as to avoid the actual size of the image being changed due to the reduction of the image size during import and recognition operation.

2. For customers with high dimensional requirements, a production process meeting must be held to ensure that relevant links of production attach great importance to it. The ink-jet typesetting documents shall not be arranged too long. The stepping parameters of the ink-jet eco solvent printer shall be adjusted well and shall be controlled within a section of three meters.

3. For the small format advertising spray-painted posters that need to be die-cut, because customers are extremely sensitive to size or pattern, they must strictly prevent lengthening or shortening. Before production, test the correctness of parameters and strengthen sampling inspection. Carefully check, operate and spray painting production strictly, and minimize irrelevant errors affecting the size of the spray printing output of the eco solvent printer.

Zhengzhou New Century Digital( Skycolor Eco Solvent Printer: www.century-printer.com ) Focus on Skycolor Eco Solvent Printer have already used in advertisement for more than ten years . The products have passed ISO9000 and CE certification, owning the trust of most consumers.

The Skycolor Eco Solvent Printer team has an excellent R&D team and a complete production and after-sales service system. It introduces new industry-leading technologies every year, and also participates in many industry exhibitions, showing new products and new technologies. The printing field has built an industry leading position. Skycolor Eco Solvent Printer has many hot-selling models.